Why Dental 3D Printing Is a Smart Investment

LET’S START BY EXPLAINING WHAT IS DENTAL 3D PRINTING

Dental three-dimensional (3D) printing, also referred to as additive manufacturing (AM), is a cutting-edge technology revolutionizing the field of dentistry. It involves the precise layer-by-layer fabrication of dental prosthetics, models, dentures, and aligners using specialized 3D printers. At WELNOX, we use this innovative approach not only to streamline the traditional, labor-intensive processes but also to allow for a high level of customization and accuracy, ultimately improving patient outcomes and comfort. However, our 3D printer is only one piece of the puzzle that constitutes a digital dental office. Digital dental technology encompasses a series of equipment, principles, and techniques that enable us to create patient-specific solutions with greater efficiency and precision.

WELNOX DIGITAL DENTAL OFFICE - THE ESSENTIALS

The purpose of our office is to provide overall wellness with an emphasis on oral health and its impact on our health. As such, patient experience and comfort are as important as the long-term success of our treatment. We can achieve that by incorporating digital tools and leveraging fully digital workflows. Our office uses a combination of hardware, software, and protocols to streamline operations and enhance patient care:

1. Intraoral scanning:

The first step of digital technology starts with intraoral scanning of all patients who come into our office as a standard procedure for our initial exam or consultation. This protocol provides excellent patient education leveraging visualization of intraoral structures for the first time and it’s utilized for diagnostic digital planning and designing. Additionally, all final impressions are made digitally using our intraoral scanners, eliminating the need for conventional impressions, improving patient comfort, and increasing efficiency with the lab team.

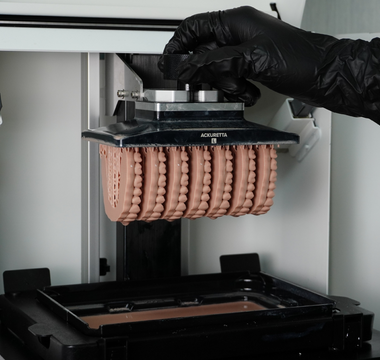

2. 3D Printing:

Our Ackuretta SOL 3D printer is used daily for in-house production of dental diagnostic models, occlusal guards, surgical guides, and temporary restorations like crowns and fixed dental prostheses.

3. Digital Radiography:

We utilize digital radiographs to enhance image quality, reduce radiation exposure, and simplify the storage and retrieval of X-ray images.

4. High-tech Monitors:

We installed monitors within the treatment rooms to display digital images, radiographs, digital smile designs, and before & after pictures enabling real-time discussions with patients and improving their understanding of their dental health.

5. Communication Tools:

We implemented virtual communication tools for patient outreach, appointment reminders, and follow-up.

6. Cybersecurity Measures:

We ensured robust cybersecurity protocols to protect sensitive patient data and comply with privacy regulations.

By embracing these essentials, our digital dental office enhances patient care, improves operational efficiency, and stays at the forefront of technological advancements in the field of dentistry.

WHY IS 3D DENTAL PRINTING ESSENTIAL AT WELNOX?

Before starting WELNOX, I was the founding director of the Graduate Prosthodontic Program at the University of Pennsylvania School of Dental Medicine - where I developed and implemented a complete digital curriculum that became very popular among prosthodontic applicants.

After over a decade of conducting studies published in peer-reviewed journals on digital dentistry, implementing these technologies in my everyday practice was not only natural but essential. With this experience, 3D printing was an instant addition and smart investment for our team at WELNOX for several compelling reasons.

First, it significantly reduces time and material costs making it a cost-effective alternative to traditional methods of fabricating diagnostic models, temporary restorations, or occlusal guard appliances. After an initial intraoral scan is made, the digital files are instantly shared with the dental laboratory technician to start the design phase. As soon as the diagnostic design is completed and approved, the files are sent back to our office for 3D printing. This process has the least turnaround time allowing the treatment to progress or be completed faster than ever before.

Furthermore, in-house manufacturing allows increased control over the production process, material selection, and post-processing details ensuring the most accurate and reliable result. For implant surgeries, after the virtual planning is completed by superimposing intraoral scans and CBCTs, the surgical guide files are used to be printed in-office as well. As printable dental materials are constantly being improved new ones are tested and added to our armamentarium allowing even the possibility for long-term or definitive restorations.

WHY WE ARE USING A 3D PRINTER?

Integrating a 3D printer into WELNOX offered several significant advantages, making it a valuable investment for our practice:

1. Customization:

3D printing allows us to create highly customized solutions tailored to the unique needs of our patients. This level of personalization can lead to better treatment outcomes and patient satisfaction.

2. Faster Turnaround Times:

With our in-house Ackuretta 3D printer, we significantly reduce turnaround times for creating dental appliances. This not only benefits our practice by increasing efficiency but also provides patients with quicker access to their needed dental work.

3. Quality Control:

We have direct control over the production process, ensuring the quality of the dental products meets your standards. This reduces the risk of errors and the need for costly remakes.

4. Cost Savings:

While the initial investment in a 3D printer can be significant, over time, it can lead to cost savings. We reduced expenses related to outsourcing dental lab work and material wastage, and we will potentially increase our practice's revenue by offering more in-house services.

5. Competitive Edge:

Embracing the Ackuretta SOL 3D printing technology sets WELNOX apart from competitors and positions us as an innovative, cutting-edge dental provider. This can be attractive to patients seeking advanced and efficient dental care.

Support and open communication are paramount when partnering with a digital technology company. Ackuretta Customer Success Team is always available to answer questions, troubleshoot, or connect me with other experts on 3D printing such as laboratory technicians or dentists.

CASE REPORT

Our patient had extensive caries on #12 and symptomatic apical periodontitis. The tooth was diagnosed with irreversible pulpitis and received endodontic treatment. After the build-up was completed, a full-coverage crown was recommended to ensure a good long-term prognosis.

An intraoral scan (NEOSS 2000) was used to make a digital impression of the prepared tooth, opposing dentition, and occlusion

The files were electronically shared with the technician who designed the new crown and returned within 24 hours. The file was imported to ALPHA AI software and used the crown feature to set up the print.

The resin material was poured into the vat and the table was mounted. After the printing was completed, the crown was inspected to ensure it was successfully printed. The post-printing processing included 3 minutes in an alcohol bath, a thorough rinse and dry, the removal of the supports, and light-curing based on manufacturer recommendations.

The crown was finished by polishing sequentially with from coarse to fine finishing burs until high shine was achieved.

During the insertion appointment, the interim was removed, preparation was pumiced, and the 3D printed crown was tried in. A radiograph was taken to verify the margin and the patient approved the esthetics.

The crown was placed in an alcohol bath in preparation for final cementation and was bonded with dual-cure resin cement (Panavia V5).

It was light-cured and excess cement was removed. Occlusion was verified and final adjustments were made. The patient was very satisfied with the result and the timeframe in which the treatment was completed utilizing a fully digital workflow.

About Ackuretta

Ackuretta is a global manufacturer of high-precision 3D printing solutions for dental professionals. Our high-quality “plug-and-play” solutions bring the world of additive manufacturing and same-day dentistry to our global network.

With validated and calibrated workflows, an open system, and outstanding training and customer support, Ackuretta is a unique, and competitive player in the industry. Visit our website to learn more.

Sign up for the Ackuretta Insight Newsletter to receive the latest updates on product launches, promotions, events, and more.

For more information, please contact: marketing@ackuretta.com

References:

Anadioti E, Kane B, Zhang Y, Bergler M, Mante F, Blatz MB. Accuracy of Dental and Industrial 3D Printers. J Prosthodont. 2022 Mar;31(S1):30-37.

Anadioti E, Musharbash L, Blatz MB, Papavasiliou G, Kamposiora P. 3D printed complete removable dental prostheses: a narrative review. BMC Oral Health. 2020 Nov 27;20(1):343.

Anadioti E, Aquilino SA, Gratton DG, Holloway JA, Denry IL, Thomas GW, Qian F. Internal fit of pressed and computer-aided design/computer-aided manufacturing ceramic crowns made from digital and conventional impressions. J Prosthet Dent. 2015 Apr;113(4):304-9.

Anadioti E, Aquilino SA, Gratton DG, Holloway JA, Denry I, Thomas GW, Qian F. 3D and 2D marginal fit of pressed and CAD/CAM lithium disilicate crowns made from digital and conventional impressions. J Prosthodont. 2014 Dec;23(8):610-7.

Loading ...

Loading ...