Uses of 3D Printed Dental Models:

From Aligner Production to Patient Education

Introduction

In recent years, 3D printing technology and digital dentistry workflows have transformed dentistry. 3D printed dental models have emerged as a game-changer for practices that can now produce these applications chairside on the same day while spending less time and resources. Dental Models are used for significant roles in a practice such as for treatment planning, dental research, the production of well-fitting aligners and crowns, and the creation of wax-ups. A key role of dental models is to help patients better understand their oral health condition and potential treatment options.

What is a Dental Model?

A dental model is a physical three-dimensional representation of a patient’s oral anatomy that practitioners can use to closely review the dental occlusion and teeth alignment. A model can also serve as a clinical, and if needed legal, record to aid in the diagnostics and planning of treatment for orthodontic, prosthodontic, or oral maxillofacial surgery. The dental model is routinely used by practitioners to simulate the fabrication of dental applications such as crowns or aligners.

The Impact of 3D-Printed Dental Models

Traditionally, dental impressions were taken using imprecise plaster molding techniques which often led to inaccuracies in the resulting models. Compared to this previous method, 3D printed models have a higher level of detail and will degrade slower than a plaster model. Digital dentistry techniques, specifically dental 3D printing, have improved the model fabrication process, saving users time, money, and material resources.

Digital impressions have significantly improved the accuracy and fit of models and manufactured restorations or removables. With the rapid adoption of intra-oral scanning in dental offices in the last 10 years, and the increasing availability of free or low-cost Dental CAD software, creating dental models in-house has become an easy adoption for dentists and technicians.

The intuitive and simple workflows of freely available CAD software made the process of creating highly accurate and detailed models of a patient's teeth easy. The digitally captured oral structures provide a comprehensive representation of a patient’s dental condition and same-visit printing also allows for a more immediate diagnosis and treatment planning. Patients have the opportunity to visualize their oral health situation. This saves the time usually needed to send an order to a lab and wait for them to produce and allows clinics to achieve same-day production of dental models.

3D printed and model-specific dental resins enable the in-house production of dental models in a fast, efficient, and cost-effective manner that equals out to less than $2 per model.

The Advantage of Dental Models

The primary advantage of 3D printed dental models is their function to replicate the patient's unique dental anatomy with exceptional precision. The model can be analyzed to identify issues such as misalignments, malocclusions, or irregularities in tooth structure that may not be immediately apparent in traditional diagnostic methods. This level of detail enables a more thorough understanding of the patient's dental condition, facilitating a more informed and personalized treatment approach.

3D Printed Models for Dental Education: Patients & Students

The advent of 3D-printed dental models has transformed patient education and communication within the dental practice. In the past, explaining dental procedures and treatment plans to patients often relied on printed or computer images or verbal descriptions. With the availability of physical dental models, dentists can offer tangible and visual representations of the patient's oral condition.

Visual 3D replicas not only improve patient understanding but also foster a sense of collaboration in treatment decisions. Patients can hold and examine their 3D-printed dental models, look closely at how their teeth are aligned, and gain a clearer insight into their oral health, the benefits of good oral hygiene, and the outcomes of proposed interventions. This hands-on approach enhances communication between the practitioner and patient, allowing both parties to have a mutual understanding of a proposed procedure and expected outcomes.

3D-printed dental models have also become valuable assets in dental education and training. Dental students can benefit from realistic hands-on experiences by practicing on precise and accurate 3D printed models that simulate various dental conditions. This immersive learning approach enhances skills and is a beneficial preparation for real-world clinical scenarios. Dental professionals can also use dental models for continuous education and training, staying abreast of the latest techniques and advancements in the field.

Other Uses of 3D-Printed Dental Models

Treatment Planning

3D-printed dental models have become indispensable tools for precise treatment planning. By converting medical imaging data into three-dimensional models, surgeons can visualize the patient's anatomy in unprecedented detail and practice on a personalized model before the actual surgery. Models can assist in the simulation of a multitude of treatment scenarios that allow for the evaluation of treatment options before implementation. This aids meticulous planning for restorative treatments, reducing the margin of error and ensuring optimal outcomes for the patient.

Aligner Production

Aligners have become an incredible option for patients to change their smiles without the commitment to metal braces. The rapid development of aligner providers, such as Invisalign, Clear Correct, etc. clearly indicates the popularity of aligner treatment.

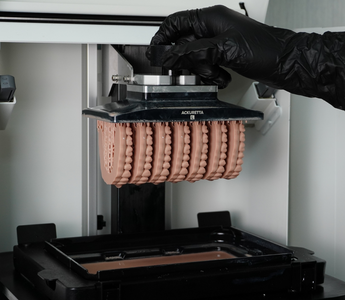

However, orthodontists and orthodontics technicians have the opportunity to in-house create dental models for aligner production at a minimal cost. A single 3D printer with the capacity of 8 full arches per print, can produce enough models for a full aligner case within just a few hours. Additional equipment will be required for the suck-down thermoforming process, however, the return is a highly lucrative and continuously growing patient segment.

Wax-ups

3D-printed dental models have become a common tool used for wax-ups. The precision enabled by a 3D printed model allows the creation of a wax-up that closely resembles the patient’s teeth, gums, and surrounding structures, to provide an authentic representation of the planned restoration. By applying wax directly to the model, a technician can shape and sculpt the restoration according to the design made in the CAD software. This approach allows for fine-tuning and adjustments based on the unique characteristics of the patient's dentition.

Smile Design Wax-ups (Crown, Bridges, Veneers)

A key feature in digital smile designs is the creation of wax-ups to not just digitally show patients their potential smiles but to create replicas of what a “new and improved” smile could look like. In many cases, the ability to create immediate wax-ups for cosmetic cases has created a significant advantage in case acceptance among patients.

With the adoption of intra-oral scanners, facial scanners, and digital planning software, the options for cosmetic smile design are vastly improved. However, touching and seeing how 3D printed (potentially only provisional) crowns, bridges, and veneers look and feel is unbeatable for a patient. 3D printing allows for the opportunity to “test drive” a smile even before any final preparation has been done. These cases are often showcased on social media by leading digital dentists, such as Dr. Wally Renne (Founder of the MOD Institute) and Prof. Adam Nulty (President of IDDA).

To learn more about how to adopt smile design workflows, we recommend watching our Webinar with Prof. Adam Nulty about Restorative 3D Printing.

Research and Development

3D-printed dental models have opened new avenues for research and development in dentistry. Researchers can utilize these models to simulate different dental conditions, conduct experiments, and test innovative treatment approaches. This ability to replicate diverse oral conditions with precision enhances the reliability of research findings and contributes to the evolution of dental practices.

Ackuretta’s 3D Printing Solution

Dental 3D Printing has made the production of high-quality, precise, and accurate dental models easier than ever. Providers that offer an extensive workflow covering many of the actions in the 3D printing process simplify production for practitioners even further, increasing productivity and profitability.

Ackuretta is an example of a provider that offers a comprehensive 3D Printing Solution, which allow a user to easily transition from slicing to printing to post-processing. The trusted manufacturer of high-precision products recently launched its Plus Family suite of products which includes the SOL Plus 3D Printer, CURIE Plus UV Curing Oven, and CLEANI with Tank Plus to combine with its ALPHA AI slicing software and CURO line of resins.

With this complete 3D Printing Solution, users can prepare prints on ALPHA AI and print up to 28 high-quality dental models at once on SOL Plus’ new XL Build Platform, wash them in bulk using CLEANI Tank Plus, and cure up to 8 full arch models simultaneously in CURIE Plus.

These advancements have not only simplified workflows for dental clinics and labs, but they have increased accessibility and empowerment of patients by reducing barriers to access and increasing understanding of patient oral health and potential treatment possibilities.

Conclusion

3D-printed dental models have ushered in a new era of precision, efficiency, and innovation in dentistry. The proliferation of physical models made possible by Dental 3D Printing has contributed to a revolution in patient education, making dental conditions and treatment options real for patients without adding extra work for practitioners. From surgical treatment preparation to patient education and dental research, 3D-printed models have become an indispensable tool for both clinics and labs. As Dental 3D Printing technology continues to improve and be adopted by clinics and labs, usage of 3D printed applications such as dental models will increase further, shaping the landscape of dental care and improving outcomes for patients worldwide.

Loading ...

Loading ...