Dr. Tiang's Take on 3D Printing - Part 1

Low-Cost vs. Premium

Dr. Steve Tiang, an experienced digital dentist, shares his wisdom all about what makes or breaks a great 3D printing experience and answering the most pressing question: how much should I pay for a premium product?

With 20 years as a dentist and 18 years using CEREC as a digital dentist, I decided to start my 3D Printing journey with a low-cost LCD printer just a few years ago.

I figured if it ended up 'not for me', it wasn't too much money wasted. Printing with that printer was a steep learning curve. I watched a number of YouTube videos and was lucky to be able to bounce ideas off some knowledgeable colleagues as I tried to wrap my head around the basics.

In the beginning, I enjoyed the challenge and have spent countless hours on weekends and evenings printing and learning; learning, and printing. At this point, I should acknowledge my partner for her patience and understanding :p Every new resin would have to go through the same process of optimising the exposure and scaling the print. When dental resins are so expensive, it's not just a time-consuming process!

When the opportunity arose to get to upgrade to a “4K” printer for extremely cheap, I jumped at the chance. But this ended up as yet another steep learning curve as I found the build plate was too smooth, much harder and the stock FEP was “stickier”. Actively scoring the build plate helped, as did later swapping the FEP to a sheet of nFEP. It made me realise that my colleagues who were struggling with these low-cost printers had legitimate reasons.

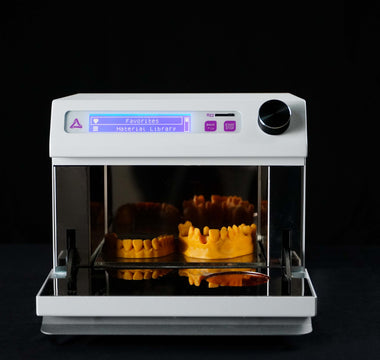

Recently, I decided it was time to get a dedicated dental 3D Printer with validated resin workflows. Being in several 3D printing and dental Facebook groups, I was able to follow the reported pros and cons of some of the more expensive printers. After some colleagues posted about the results, they were getting from the Ackuretta SOL printer, I decided this was the 'next step' printer I would get as it appeared to give excellent prints; was a “plug and play” printer that had validated resin profiles for over 100 different dental resins; is cheaper than the other dental-specific printers; has excellent support from knowledgeable staff.

What I've Found is that you get what you pay for.

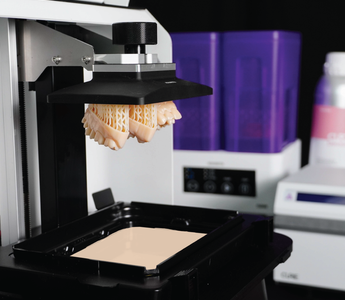

On receiving the SOL, I was highly impressed with the build quality.

Having spent significant time with other slicing software, using the Alpha 3D slicer was very straightforward. There are other options that have a few more user-configurable options but I don't find there's much in the day-to-day use of Alpha 3D that is left wanting. One major advantage of Alpha 3D is the software stability – no random crashes!

The quality of a 3D printer is defined by 5 key aspects:

3D Printer Components & Specs

Slicing Software

Material Calibration

Or the lack thereof...

Tech Support

Or again, the lack thereof...

Availability of an end-to-end 3D printing solution

Including post-processing equipment & resins

Components & Specs

The quality of materials used in the cheap printers is noticeably inferior. There’s plenty of cases of 3D printers with lids that let UV light penetrate which partially cures the resin in the vat. Having to spray paint or cover the entire printer really isn't good enough, in my opinion.

There have also been many cases where the body of the printer has developed large cracks. I assume this might be a result of the resin damaging the printer or the plastic being under tension from the factory. Either way, cheap plastics that are at risk of cracking are a concern.

Another recent concern with many different low-cost printers is Z-wobble. The entire z tower/rail assembly flexes during the printing process and can cause distortion and waviness of the prints. Having to buy an “upgrade kit” to remedy this is also not really good enough, especially when the upgrade kit plus shipping costs nearly half of the price of the printer to start with.

The durability of the LCD screens for cheaper printers is rated in the hundreds of hours for RGB and “up to” 2000 hours for monochrome printers. User reports show that 2000 hours estimate might be a little on the optimistic side but at the same time, I wouldn't be surprised if the screens were damaged through user error. This isn’t to say that cheaper 3D printers are not good printers, but the US$4000 price difference has a visible impact on the quality and longevity of your product.

By paying a higher price, you can purchase a dental 3D printer that provides detailed information in case there is a need for maintenance, and the parts of the printer promise longer durability. I’ve only received my Ackuretta SOL printer several weeks ago, so naturally, nothing has given me any problems yet. Ackuretta claims that the LCD can withstand up to 10,000 hours of printing - a claim that I plan to put to the test.

Even when I do manage to burn out the screen, I was happy that the printer comes with a spare screen as well as a second resin vat. The construction of the Sol is robust and high quality both in appearance and feel.

If you want to read more about the comparison of SOL vs other printers, check out the article Monochrome vs RGB Dental Printers.

Successful prints come from much more than just pixel size.

When it comes to specs, the newer printers are aiming to surpass each other on resolution stats. You'll find a lot of 3D printers are now advertised similarly to new TVs - they claim, the higher the resolution, the better the result. While 4K and 8K sound impressive but have little impact on your 3D print. A very well-known 3D printer from the DIY section advertises a 4K resolution - and delivers a 76 micron XY resolution - a less impressive spec than what can be found in more specialized 3D printers - the SOL LCD screen pixel size is 49 micron.

Marketing aside, it's the results that count and successful prints come from much more than just pixel size.

Printing Speed - I think we all want fast 3D printers.

It’s another thing that's kept me from going with other big brand names in the industry. The low-cost hobby printers have long been outperforming their very expensive counterparts. But now, as I can show in my latest comparison tests, the SOL dental 3D printer performs faster and deliver consistently reliable results.

Slicing Software

There are pros and cons to each slicing software package.

It does make sense to work with dental-specific software. Ackuretta’s Alpha 3D comes with all calibrated resins for each printer with an easy drop-down menu.

The auto-support function removes most manual work and requires the user to only make slight adjustments.

Want to know more about Dr. Tiang's take on 3D printing? Stay tuned - Part 2 will be released Dec. 15th.

About Dr. Tiang

Dr. Steve Tiang is based in Waikato, New Zealand and acts as principal dentist at North Care Dental Center.

His particular interests lie with high tech dentistry especially CEREC CADCAM crown, bridge, and implant restorations; high quality root canal therapy; and soft tissue laser therapy.

Loading ...

Loading ...