3D Printing – Difference Between SLA, DLP, and LCD

You've probably heard of LCD, SLA and DLP 3D printers - but what's not clear: which one is most suitable for your dental office or lab? And which specs matter? We’re here to help you out.

SLA, LCD, and DLP are the most commonly used 3D printing technologies in the dental industry. All three use photosensitive resins, which means that layer by layer is cured using a light source. This process transforms liquid resins into solid layers and, eventually, whole parts. This makes it sound like the 3 technologies are the same – but they’re not.

quick Facts

3D Printer Types

Stereolithography (SLA)

SLA was the first 3D printing technology produced. Since it was first developed in the 1980s, not much has changed. Unlike DLP and LCD technologies, the light source used is a laser. The laser beam sweeps across the resin tank and solidifies the material layer by layer.

Digital Light Processing (DLP)

Digital Light Processing was invented in 1987 by Texas Instruments and originally applied in the production of projectors.

In 3D printing, DLP does not use a laser, but a projector. The moment the light hits the resin, it’s not restricted to a single spot as with SLA. Instead, the whole layer is formed at once. Here, patterning of the illumination is critical to achieving the desired shape for each layer.

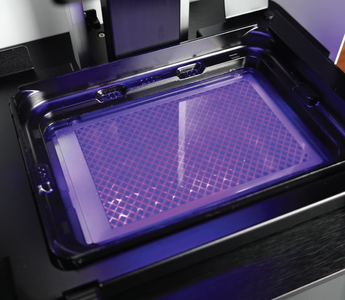

This is accomplished by using a “mask”, which is produced by a digital micromirror device (DMD). This part sits between the optical path of the lamp and the resin. One example of a high-volume producing DLP printer is Ackuretta’s DIPLO, seen in the image above.

Liquid Crystal Display (LCD)

LCD 3D printing is very similar to DLP, as it flashes entire layers at once curing resin inside the resin tank. What differentiates the two technologies is the light source.

LCD technology does not employ a projector, but an array of LEDs exposing the UV light through an LCD screen. The screen only lets the light pass through areas that are to be cured, simplifying the process and removing the need for any moving parts.

However, not all LCD 3D printers are specialized dental 3D printers. There is a low-price segment of 3D printers for DIY purposes, which come without any resin profiles for biocompatible dental resins.

Ackuretta focuses on dental 3D printers at an affordable price point. We are dedicated to ensuring that DENTIQ and SOL are validated for the newest & best dental resins on the market and provide in-depth customer training to ensure safe & biocompatible applications for patients.

Quality Output

In reality, the print quality of an LCD 3D printer compared to a DLP or SLA 3D printer depends on the 3D printer used and its components.

The 3D print quality is heavily influenced by four key factors: resolution, accuracy, precision, and maybe less importantly, speed. Thus, finding a printer that fulfills the standards you set for your dental applications, has to be measured along with those criteria. Plus, any 3D printer will only perform well if it is paired with a good CAD design, high-quality resins, and a well-executed post-processing procedure.

For more in-depth articles on resolution, accuracy & precision of each printer, click here.

Speed

DLP printers are the fastest in the 3D printing industry – at a rate of 30 to 60 mm/hour. You start to really compromise on accuracy and precision with any print larger than 200 x 120 mm.

However, dentistry is not an industry that forgives inaccuracy, which is why we recommend LCD 3D printers, like our Ackuretta – SOL and DENTIQ.

Accuracy and Precision

In 3D printing, accuracy describes the ability of a printer to print as close to the CAD design as possible. Precision then describes the repeatability of these results.

Over time, all type of 3D printers have improved on these specs significantly, but some printers decay quicker than others based on the quality of their components.

LCD 3D printers for dentistry, like SOL and DENTIQ, are calibrated for high accuracy & precision with quality components that ensure the longevity of each machine (you can read more about 3D printer quality features here). DLP printers due to the nature of the light distribution have traditionally the lowest levels of accuracy & precision.

XY Resolution

For LCD 3D printers the pixel size of the LCD print screen is the defining factor for XY resolution. DENTIQ by Ackuretta prints at 47 micron and SOL at 49 micron. For DLP printers XY resolution is determined by the pixel size of the tiny mirrors on the DMD.

The resolution has only a very minimal impact on the accuracy of the print. Its major role in 3D printing is the smoothness of the application’s surface. High-end SLA printers will produce parts that are smooth as silk. LCD printers coming in a close second. Comparably, DLP printers produce less smooth results and thus, are not ideal for dental applications such as temporary crowns or dentures.

Loading ...

Loading ...